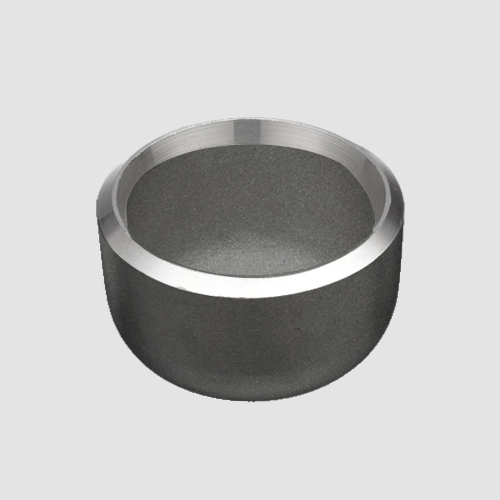

China Manufacturer of High-Quality Steam Ball Valves for Efficient Control

When it comes to reliable steam ball valves, my experience tells me that quality and performance are key. As a manufacturer based in China, we pride ourselves on delivering top-notch products that meet the rigorous demands of various industries. Our steam ball valves are designed to provide excellent flow control, ensuring safety and efficiency in operations. Crafted from durable materials, these valves offer exceptional resistance to high temperatures and pressures, making them ideal for steam applications. I've seen firsthand how our precision engineering makes a difference in reducing downtime and maintenance costs. Whether you're in energy, food processing, or manufacturing, our steam ball valves will meet your needs with reliability and strength. Partner with us for a constant supply of high-quality valves that can enhance your production line. Let’s work together to improve your operations and achieve success!

steam ball valve Market Leader Factory-Direct Excellence

In the ever-evolving landscape of industrial valve solutions, steam ball valves have emerged as a pivotal component for enhancing operational efficiency across various sectors. As the market witnesses an increasing demand for reliable and high-performance valves, the significance of sourcing from a reputable manufacturer cannot be overstated. Choosing a factory-direct supplier not only ensures quality control but also establishes a seamless supply chain that can adapt to the dynamic needs of global procurement. With a commitment to excellence, the leading manufacturers in the steam ball valve market focus on rigorous testing, innovative engineering, and sustainable practices. This dedication not only guarantees product durability and performance but also fosters trust among buyers. By collaborating directly with a top factory, purchasers can benefit from tailored solutions that align with specific project requirements, ensuring optimal performance in applications such as steam distribution, water treatment, and petrochemical processing. Furthermore, direct access to the factory allows procurement professionals to engage closely with engineers, facilitating a better understanding of product specifications and customization options. This relationship empowers buyers to make informed decisions while optimizing their supply chain efficiency. Whether you are a small enterprise or a large industrial player, sourcing steam ball valves directly from a market leader offers a strategic advantage that can enhance productivity and reduce costs in the long term.

Steam Ball Valve Market Leader Factory-Direct Excellence

| Dimension | Material | Pressure Rating | Temperature Range | End Connection |

|---|---|---|---|---|

| 2 Inch | Carbon Steel | 150 psi | -20 to 150 °C | Flanged |

| 3 Inch | Stainless Steel | 300 psi | -30 to 200 °C | Welded |

| 4 Inch | Brass | 200 psi | -10 to 180 °C | Threaded |

| 6 Inch | Ductile Iron | 150 psi | -20 to 100 °C | Flanged |

Related Products