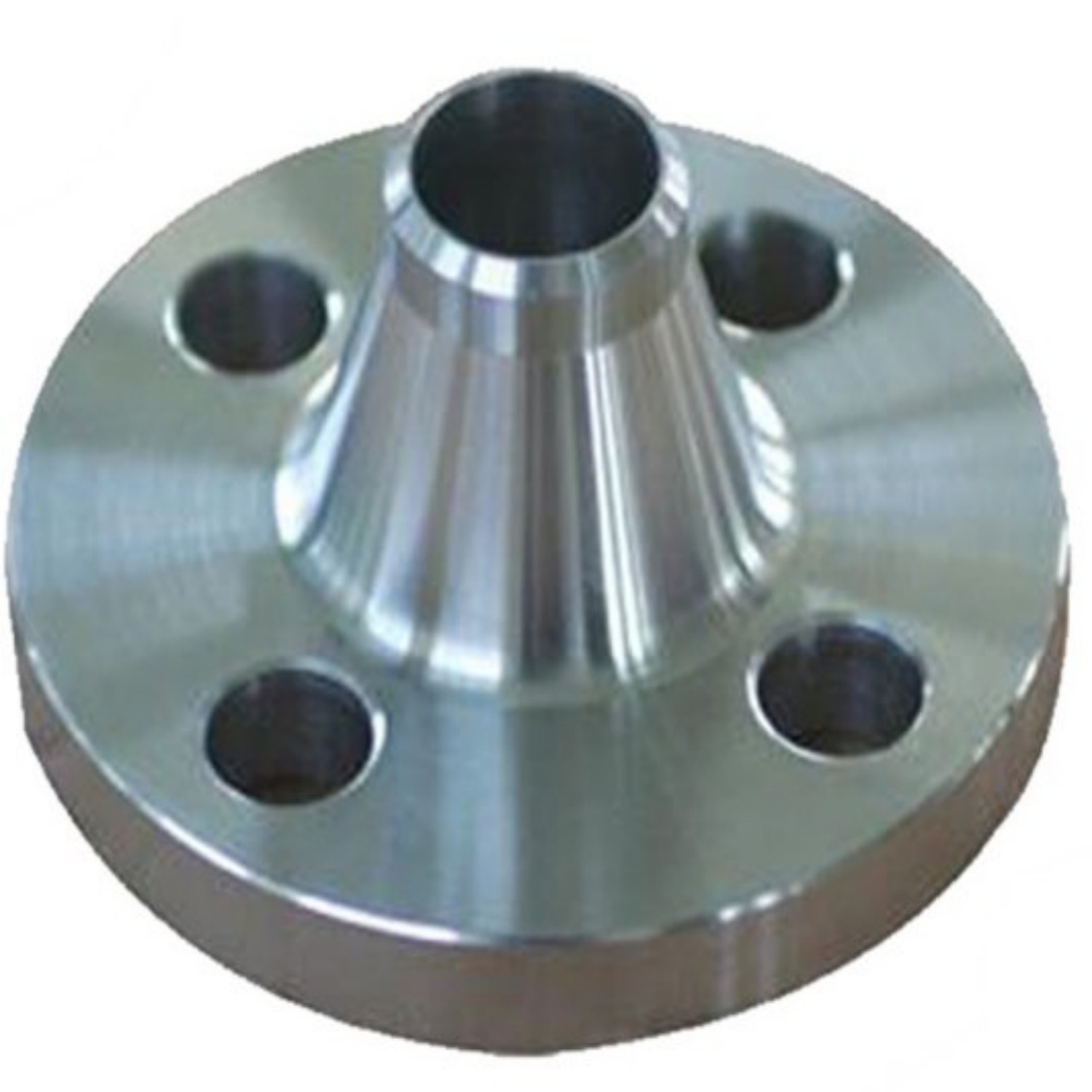

High-Quality Raised Face Flange from Trusted Supplier for Your Needs

When it comes to sourcing high-quality raised face flanges, I understand how crucial it is to find a reliable supplier that meets your expectations. Our raised face flanges are engineered to deliver exceptional performance, ensuring a perfect seal for your piping systems. Whether you’re in the oil and gas industry or requiring flanges for construction, our products provide the durability and strength you need. I know you want assurance that every component you use is built to last. That's why our raised face flanges undergo rigorous quality checks to meet industry standards. Partnering with us means you are choosing a supplier who values quality just as much as you do. Trust in our expertise and experience, and let’s ensure your projects run smoothly and efficiently. Get in touch, and let's discuss how our raised face flanges can benefit your operations.

Raised Face Flange Your End-to-End Solution Service Backed by Expertise

In the world of industrial pipelines and fluid management, raised face flanges are a critical component that ensures effective connections between different sections of pipelines. Designed to enhance the sealing of joints and minimize potential leaks, these flanges play a pivotal role in maintaining operational efficiency. Our end-to-end solution service provides not only high-quality raised face flanges but also the expertise necessary to guide you through the selection, installation, and maintenance processes. With a comprehensive understanding of industry standards and diverse client needs, we ensure that our products meet various international specifications. Our team is dedicated to providing tailored solutions that cater to your specific requirements, ensuring seamless integration into your existing systems. Whether you are involved in oil and gas, water treatment, or manufacturing, our flanges are engineered to withstand high pressure and challenging environments while delivering exceptional performance. Trust in our expertise to elevate your projects by choosing raised face flanges designed for reliability and longevity. By partnering with us, you gain access to a wealth of knowledge and a commitment to excellence that can help you navigate the complexities of procurement and installation with ease. Experience the difference of a service that prioritizes customer satisfaction while ensuring you receive the best solutions for your pipeline needs.

Raised Face Flange Your End-to-End Solution Service Backed by Expertise

| Dimension (inches) | Material | Pressure Rating (psi) | Treatment | Standards |

|---|---|---|---|---|

| 2 x 150 | Carbon Steel | 150 | Galvanized | ANSI B16.5 |

| 4 x 300 | Stainless Steel | 300 | Passivated | ASME B16.5 |

| 6 x 600 | Alloy Steel | 600 | Coated | API 6A |

| 8 x 150 | Ductile Iron | 150 | Polyester | EN 1092-1 |

| 10 x 900 | Bronze | 900 | Anodized | JIS B 2220 |

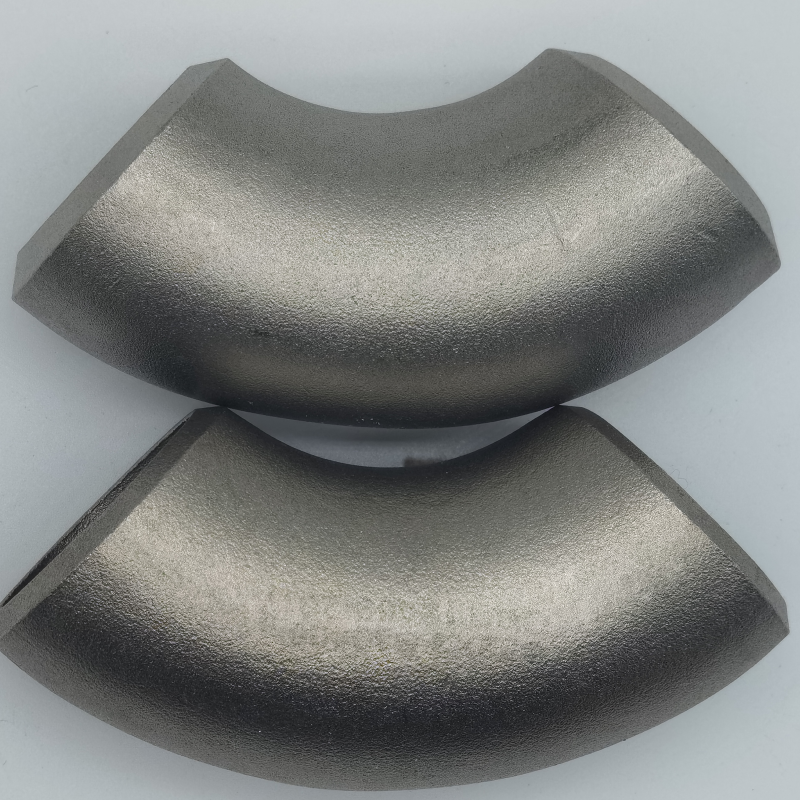

Related Products