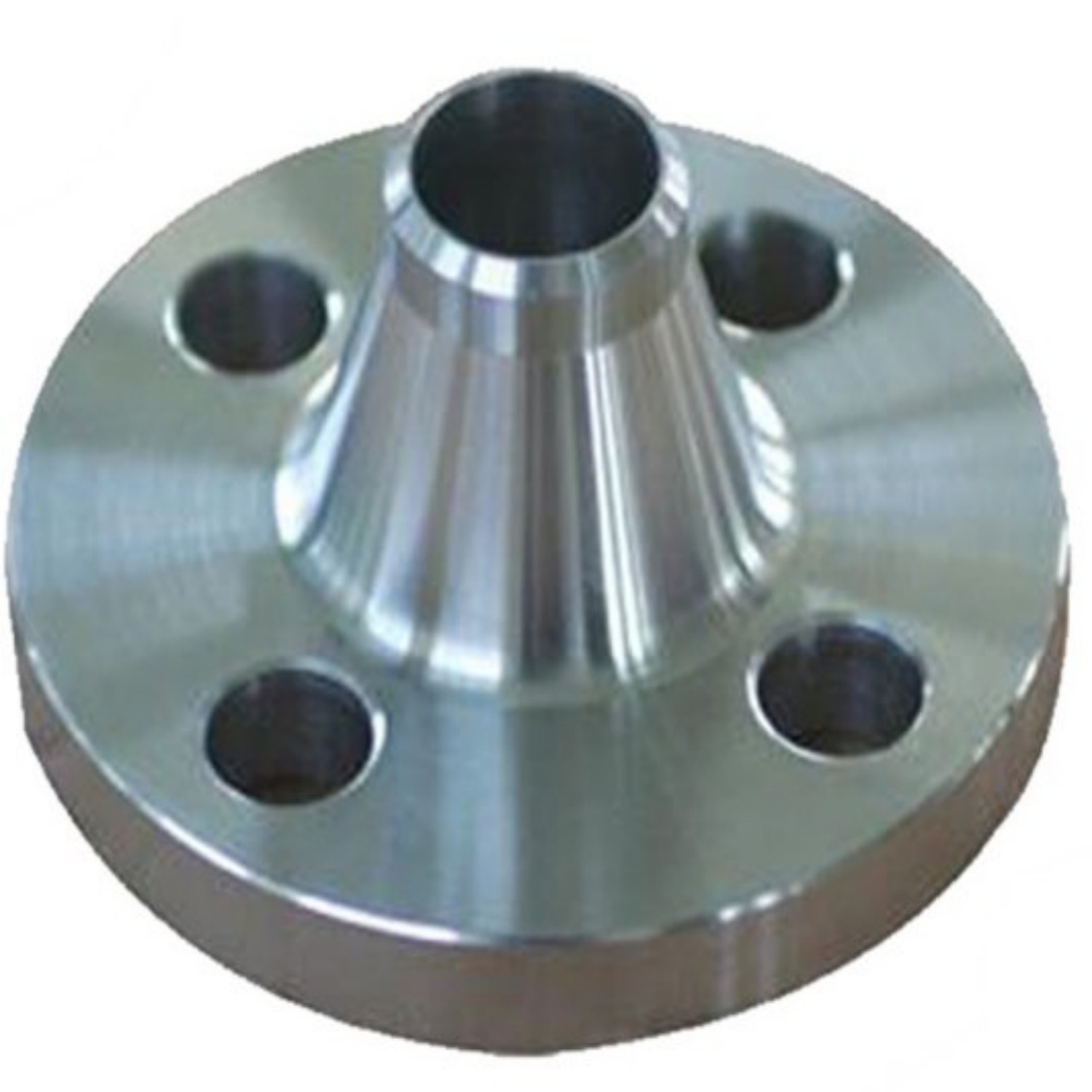

Duct Connector Flange - Trusted Manufacturer in China for Quality Solutions

When it comes to effective duct systems, the duct connector flange is essential for seamless connections and optimal airflow. I’ve found that choosing the right manufacturer from China can make all the difference in quality and reliability. Our duct connector flanges are designed with precision to ensure they fit perfectly, reducing the risk of leaks and improving overall efficiency. With strong materials that withstand various environmental conditions, these flanges are built to last. As a B2B purchaser, you want assurance that your supplier understands your needs. Our commitment to superior craftsmanship and consistency means you can trust us to deliver flanges that meet your exact specifications. Plus, our competitive pricing ensures you get the best value without compromising on quality. If reliable duct systems are what you need, these duct connector flanges from our dedicated manufacturing processes in China will not disappoint. Let’s elevate your projects together with top-notch solutions!

Duct Connector Flange Supplier Manufacturers You Can Rely On

When sourcing duct connector flanges, reliability and quality are paramount considerations for global buyers. The right supplier not only provides durable products but also ensures efficient operations through timely delivery and exceptional customer service. It's crucial to select manufacturers who adhere to international standards and have a proven track record within the industry. A supplier that invests in robust manufacturing processes and quality control will help mitigate risks associated with sourcing components. In today’s competitive marketplace, effective communication and collaboration with manufacturers can also significantly enhance procurement efficiency. Buyers are encouraged to seek suppliers who understand and can cater to their specific needs, whether it’s for standard sizes or custom manufacturing solutions. A focus on innovation in design and materials can further elevate the performance of duct connector flanges, ensuring they meet the various demands of modern applications. Furthermore, establishing a long-term partnership with a reliable supplier can lead to significant benefits, including cost savings and consistent product availability. By prioritizing these factors, global buyers can streamline their operations and enhance overall productivity. It's essential to conduct thorough research and engage with potential partners who demonstrate a commitment to excellence and customer satisfaction in every aspect of their business.

Duct Connector Flange Supplier Manufacturers You Can Rely On

| Manufacturer Location | Product Type | Material | Certifications | Production Capacity |

|---|---|---|---|---|

| USA | Flange Connectors | Stainless Steel | ISO 9001 | 5000 units/month |

| Canada | Ventilation Ducts | Aluminum | CE, ASHRAE | 3000 units/month |

| Germany | Flexible Ducts | PVC | DIN EN 1506 | 4000 units/month |

| China | Rectangular Flanges | Galvanized Steel | GB, ISO | 10000 units/month |

| India | Turned Flanges | Copper | IS 2062 | 2500 units/month |

Related Products