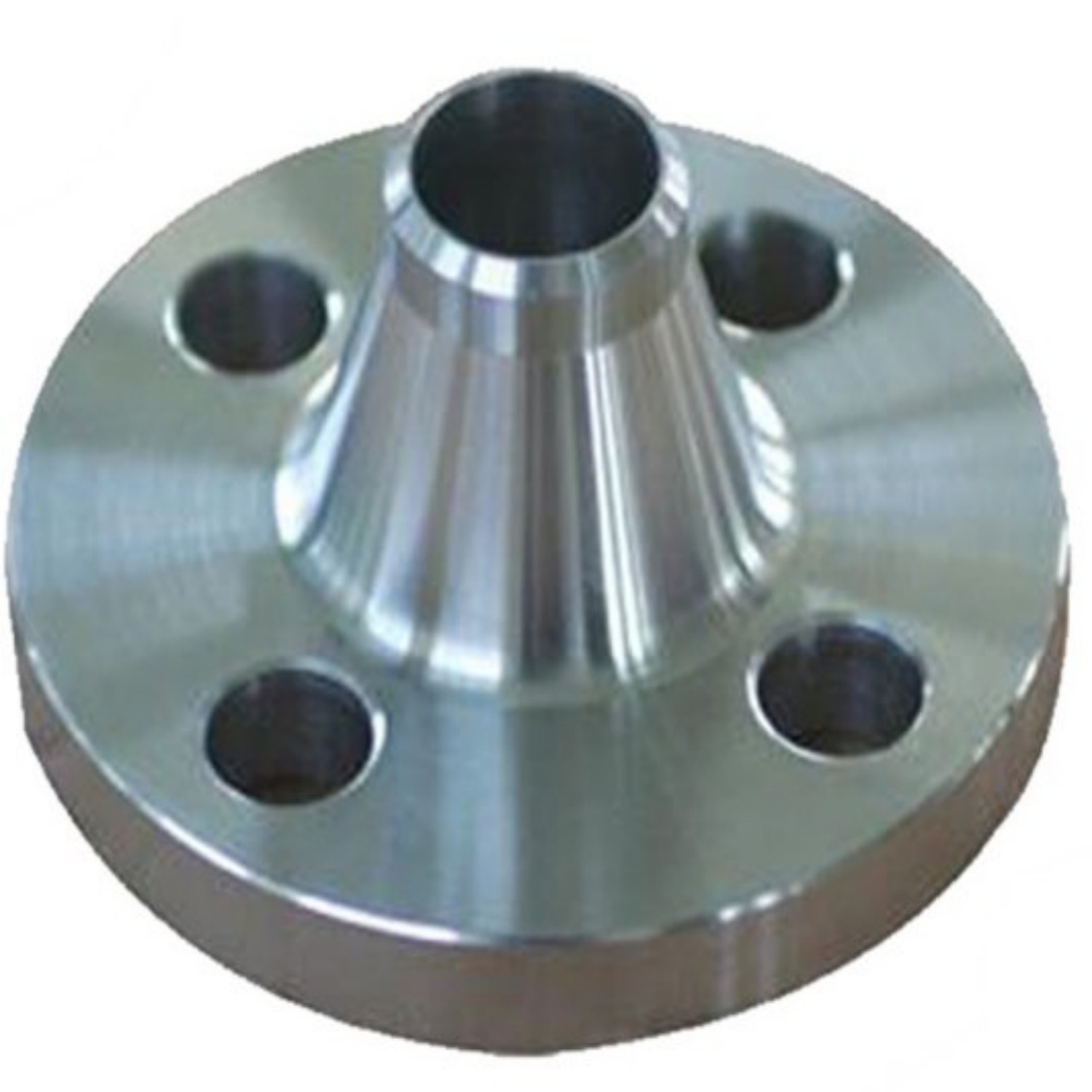

150# Flange Discounts Available from Leading Factory Manufacturers

When searching for the perfect 150# flange, I understand that quality and cost-effectiveness are key for your projects. That’s why I’m excited to offer you our high-grade flanges at unbeatable factory prices. Each flange is manufactured with precision, ensuring they meet industry standards while also being incredibly durable. I know that as a B2B buyer, finding a discount without compromising on quality is essential. Our factory-direct pricing allows us to provide you with the best deals possible, helping you to stay within budget without sacrificing performance. Whether you’re in construction, manufacturing, or any other sector that relies on reliable connections, our 150# flanges will serve your needs perfectly. Don't hesitate to reach out if you need more information or have specific inquiries about bulk purchasing – your satisfaction is my priority!

150# Flange in 2025 From Concept to Delivery

In 2025, the global demand for 150# flanges is expected to grow significantly as industries focus on improving efficiency and ensuring reliability in their operations. The evolution of flange design and manufacturing processes, aligned with the latest technological advancements, plays a crucial role in meeting this demand. From the initial concept phase to the final delivery of high-quality products, companies are committed to adopting stringent quality control measures and innovative manufacturing techniques that address the diverse needs of various sectors, including oil and gas, water treatment, and power generation. The journey of a 150# flange begins with meticulous design, considering factors such as material selection, dimensions, and application compatibility. Manufacturers are leveraging advanced software and simulation tools to enhance the design process, ensuring that every aspect meets international standards and client specifications. Following the design phase, precision machining and rigorous testing processes are implemented to ensure optimal performance and durability. This comprehensive approach not only increases product reliability but also strengthens supply chain efficiency, offering customers seamless and timely delivery. As we move further into 2025, the emphasis on sustainability and reduced carbon footprints will influence the flange market. Industries are increasingly preferring suppliers who utilize eco-friendly materials and practices throughout the production process. Companies that adapt to these changing demands by incorporating sustainable practices while maintaining excellent product quality will undoubtedly stand out in a competitive marketplace, solidifying their position as trusted partners for global procurement.

150# Flange in 2025 From Concept to Delivery

| Dimension (inches) | Material | Standard | Application | Manufacturing Method | Lead Time (Weeks) |

|---|---|---|---|---|---|

| 6 x 1/2 | Carbon Steel | ANSI B16.5 | Water Systems | Casting | 12 |

| 8 x 3/4 | Stainless Steel | ASME B16.5 | Oil & Gas | Forging | 10 |

| 10 x 1 | Alloy Steel | API 605 | Power Generation | Welding | 14 |

| 12 x 1.5 | Ductile Iron | ASTM A536 | Wastewater | Casting | 16 |

| 14 x 2 | Copper Nickel | ANSI B16.47 | Marine | Forging | 18 |

Related Products