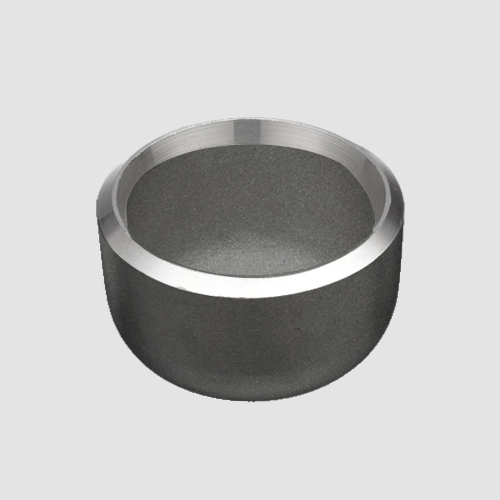

High-Quality Stainless Steel Cap from Trusted Supplier for All Needs

When I think of reliable solutions for industrial applications, stainless steel caps immediately come to mind. They offer unmatched durability and corrosion resistance, making them ideal for a variety of needs. As a supplier, I know how critical it is to provide high-quality products to meet your demands. Our stainless steel caps are crafted with precision, ensuring they fit snugly and perform optimally in all conditions. Whether you’re in construction, manufacturing, or plumbing, you’ll appreciate the consistent quality we deliver. I always strive to work closely with my clients, understanding their specific requirements to tailor our offerings. These stainless steel caps are just one of the many ways I can help you enhance your projects. By choosing our products, you're not just selecting items off a shelf; you're investing in quality and reliability. Let's connect and see how we can support your business with high-quality stainless steel solutions.

stainless steel cap Application From Concept to Delivery

When it comes to stainless steel caps, their journey from concept to delivery is pivotal for ensuring quality and reliability in various applications. Stainless steel caps play a crucial role in pipeline systems, providing a secure closure that prevents leaks and protects against external contaminants. Their versatility makes them suitable for a variety of industries, including oil and gas, food and beverage, chemical processing, and water treatment. The manufacturing process of these caps starts with high-quality raw materials, ensuring they meet stringent industry standards. Advanced fabrication techniques, such as precision machining and welding, create products that not only conform to design specifications but also undergo rigorous quality assurance tests. This ensures that every cap is durable, corrosion-resistant, and capable of withstanding high pressures and temperatures. Once production is complete, the caps are meticulously packaged and shipped to global customers. Efficient logistics and supply chain management are essential in this phase, guaranteeing that clients receive their orders on time, regardless of their location. By streamlining the entire process from design to delivery, businesses can confidently meet market demands and maintain strong relationships with procurement teams worldwide. This comprehensive approach ultimately secures a competitive edge in the global marketplace.

Stainless Steel Cap Application From Concept to Delivery

| Application Area | Material Grade | Cap Type | Design Specifications | Manufacturing Process | Delivery Timeframe |

|---|---|---|---|---|---|

| Food & Beverage | 304 | Hex Cap | Custom Diameter: 25mm | CNC Machining | 4 Weeks |

| Pharmaceuticals | 316L | Round Cap | Custom Diameter: 30mm | Extrusion | 6 Weeks |

| Construction | 430 | Square Cap | Custom Size: 50mm x 50mm | Forging | 5 Weeks |

Related Products