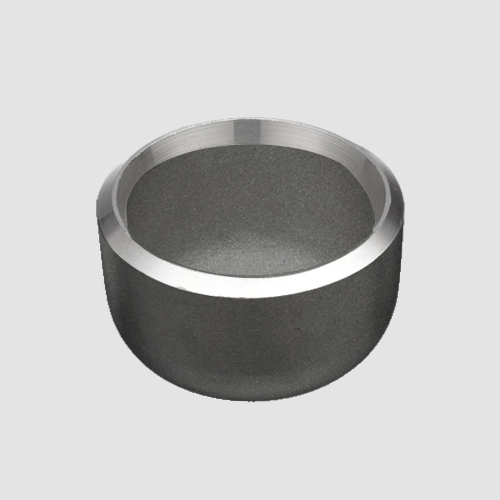

Premium Ss Seal Face Gate Valve for Factories – Durable & Reliable

When it comes to dependable performance and durability, the Ss Seal Face Gate Valve stands out in the market. As a B2B purchaser, I know how crucial it is to find high-quality products that meet our needs. This valve is designed with precision to ensure optimum sealing and can withstand high pressures, making it ideal for various industrial applications. Its corrosion-resistant materials ensure long-lasting use, perfect for both new projects and replacements. I often emphasize the importance of reliable suppliers. When I decide to buy, I always seek out factories that prioritize quality and have a solid track record. With this valve, I feel confident knowing I’m choosing a product that combines innovation and sturdiness. In today’s competitive landscape, gaining an edge means investing in components that ensure seamless operations. The Ss Seal Face Gate Valve is a smart choice for any business looking to enhance their efficiency and reliability.

Ss Seal Face Gate Valve Pioneers in the Field Service Backed by Expertise

In the rapidly evolving world of industrial equipment, innovative solutions are essential for optimizing performance and enhancing operational efficiency. Among these, the SS Seal Face Gate Valve stands out as a critical component in various applications, offering unparalleled reliability and durability. Designed to withstand high pressure and extreme temperatures, this valve type is pivotal in ensuring the smooth flow of fluids, making it a preferred choice for industries ranging from oil and gas to water treatment. What sets our SS Seal Face Gate Valve apart is the expertise and commitment to excellence that accompany every product. Our engineering team meticulously designs and tests each valve to meet stringent international standards, ensuring consistent quality and performance. The integration of advanced materials and state-of-the-art manufacturing processes allows us to deliver solutions that not only meet but exceed customer expectations. Furthermore, our global support network ensures that clients receive timely assistance and expert advice, reinforcing our dedication to service excellence and customer satisfaction. As global procurement professionals seek reliable partners in the field of pipeline equipment, the importance of selecting products that promise longevity and efficiency cannot be overstated. Our SS Seal Face Gate Valve exemplifies these qualities, making it an ideal choice for projects that demand the highest standards of performance and safety. Partnering with us means investing in a solution backed by extensive industry knowledge and a reputation for quality, helping you achieve your operational goals with confidence.

Ss Seal Face Gate Valve Pioneers in the Field Service Backed by Expertise

| Dimension | Material | Pressure Rating | Temperature Range | Application |

|---|---|---|---|---|

| DN50 | Stainless Steel | PN16 | -20°C to 120°C | Water & Oil Services |

| DN100 | Bronze | PN10 | -10°C to 80°C | Fire Protection Systems |

| DN150 | Carbon Steel | PN25 | -40°C to 200°C | Industrial Applications |

| DN200 | Ductile Iron | PN16 | -10°C to 90°C | Wastewater Treatment |

Related Products