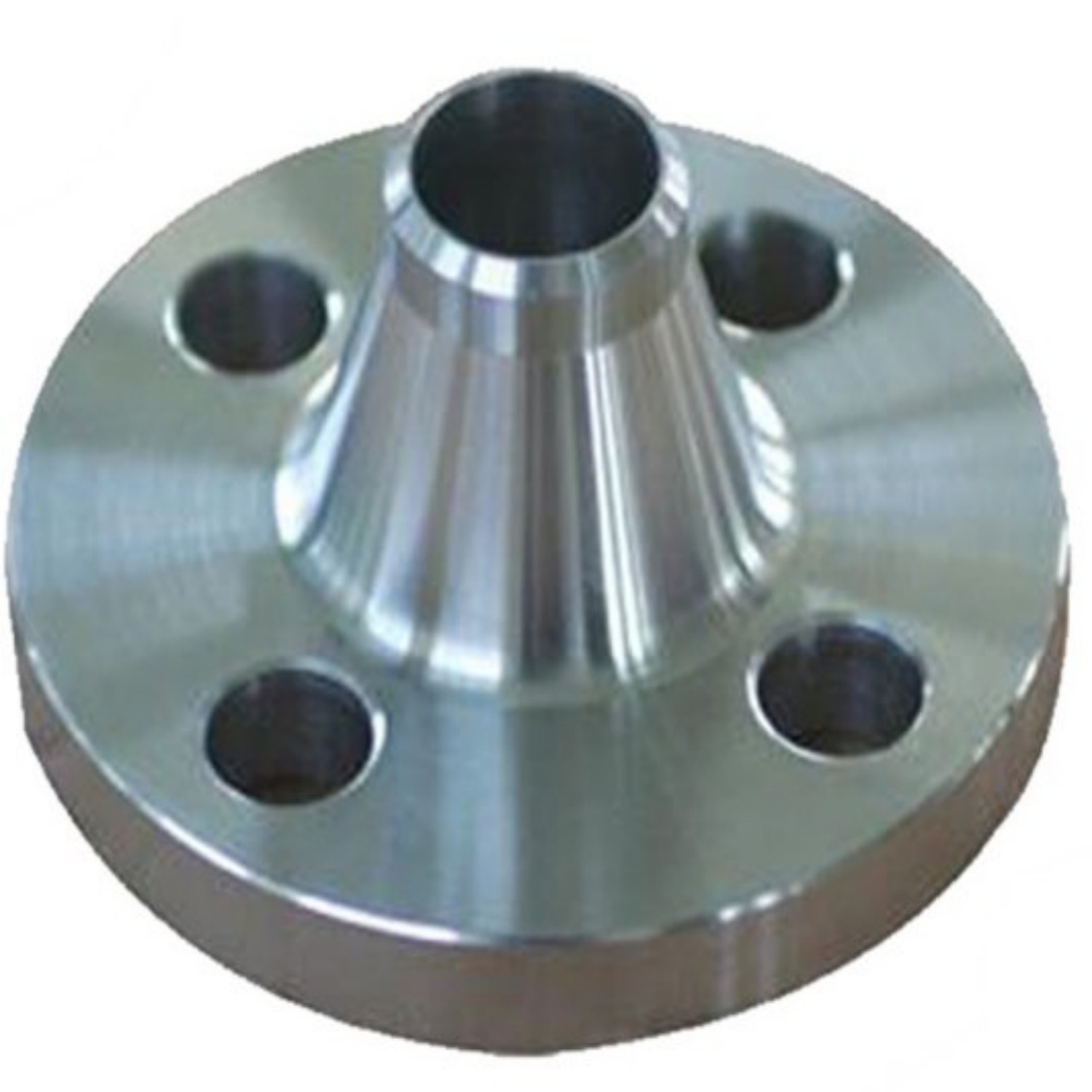

High-Quality Socket Weld Flange Supplier for Your Projects

When I think about reliable connections in piping systems, the Socket Weld Flange stands out as an essential component. Designed for high-pressure applications, these flanges ensure enhanced strength and durability. I understand how crucial it is for B2B purchasers to find high-quality products, and that's exactly what I offer. My Socket Weld Flanges are crafted using premium materials, guaranteeing they meet the strictest industry standards. As a trusted supplier, I pay attention to detail and focus on delivering products that exceed expectations. Each flange is meticulously inspected to ensure precision fit and reliability in your projects. When it comes to sourcing components that can withstand demanding conditions, I provide the quality you need. Choosing my Socket Weld Flanges means investing in long-lasting performance and peace of mind for your operations. Let's enhance your piping solutions together!

Socket Weld Flange Service Industry Leaders

In the world of industrial piping solutions, socket weld flanges stand out as a critical component for ensuring leak-proof connections in high-pressure environments. Industries ranging from oil and gas to water treatment depend heavily on the reliability and performance of these flanges. Leaders in the socket weld flange service industry understand the importance of not only providing high-quality products but also offering exceptional customer service and expertise. Choosing the right socket weld flange requires a deep understanding of material specifications, pressure ratings, and dimensions tailored to the specific needs of various applications. Industry leaders focus on utilizing superior materials that can withstand the most rigorous conditions while ensuring compliance with international standards. Furthermore, these companies often provide customized solutions, advising clients on the best practices for installation and maintenance to prolong the lifespan of their equipment. In a global marketplace, the ability to deliver dependable socket weld flanges promptly is crucial. Partnering with industry experts who prioritize innovation and quality enables procurement teams to streamline operations and enhance overall efficiency. With a commitment to continuous improvement and an eye on emerging trends, top players in the socket weld flange industry remain at the forefront, driving advancements that benefit businesses worldwide.

Socket Weld Flange Service Industry Leaders

| Service Provider | Industry Experience (Years) | Certifications | Service Areas | Customer Rating (out of 5) |

|---|---|---|---|---|

| Provider A | 15 | ISO 9001, ASME | North America, Europe | 4.8 |

| Provider B | 10 | ISO 45001 | Asia, Australia | 4.5 |

| Provider C | 20 | API, ASME | Global | 4.9 |

| Provider D | 5 | ISO 9001 | North America | 4.3 |

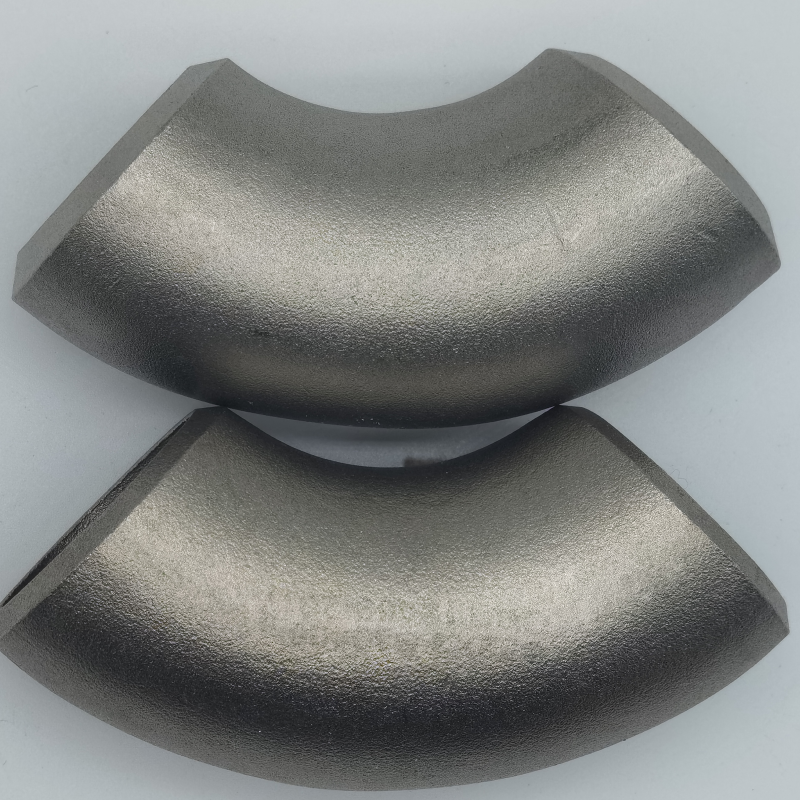

Related Products