Plate Flange vs Weld Neck Flange: Wholesale Insights from Top Manufacturers

When choosing between Plate Flange and Weld Neck Flange, it’s essential to understand their unique properties and applications. I’ve found that Plate Flanges offer a simpler installation process and are generally more cost-effective for low-pressure systems. On the other hand, Weld Neck Flanges provide superior strength and are ideal for high-pressure applications due to their seamless weld connection, which reduces stress concentrations. As a professional in the industry, I often recommend connecting with reliable wholesale manufacturers to ensure you’re getting high-quality products. Building relationships with trusted suppliers can be a game changer, helping you find the right flanges to meet your specific needs. Whether you're looking for a bulk purchase or specialized items, having the right partners makes all the difference in achieving your project’s goals. Let's make sure you're equipped with the best flanges for your operations!

Plate Flange vs Weld Neck Flange Now Trending Outperforms the Competition

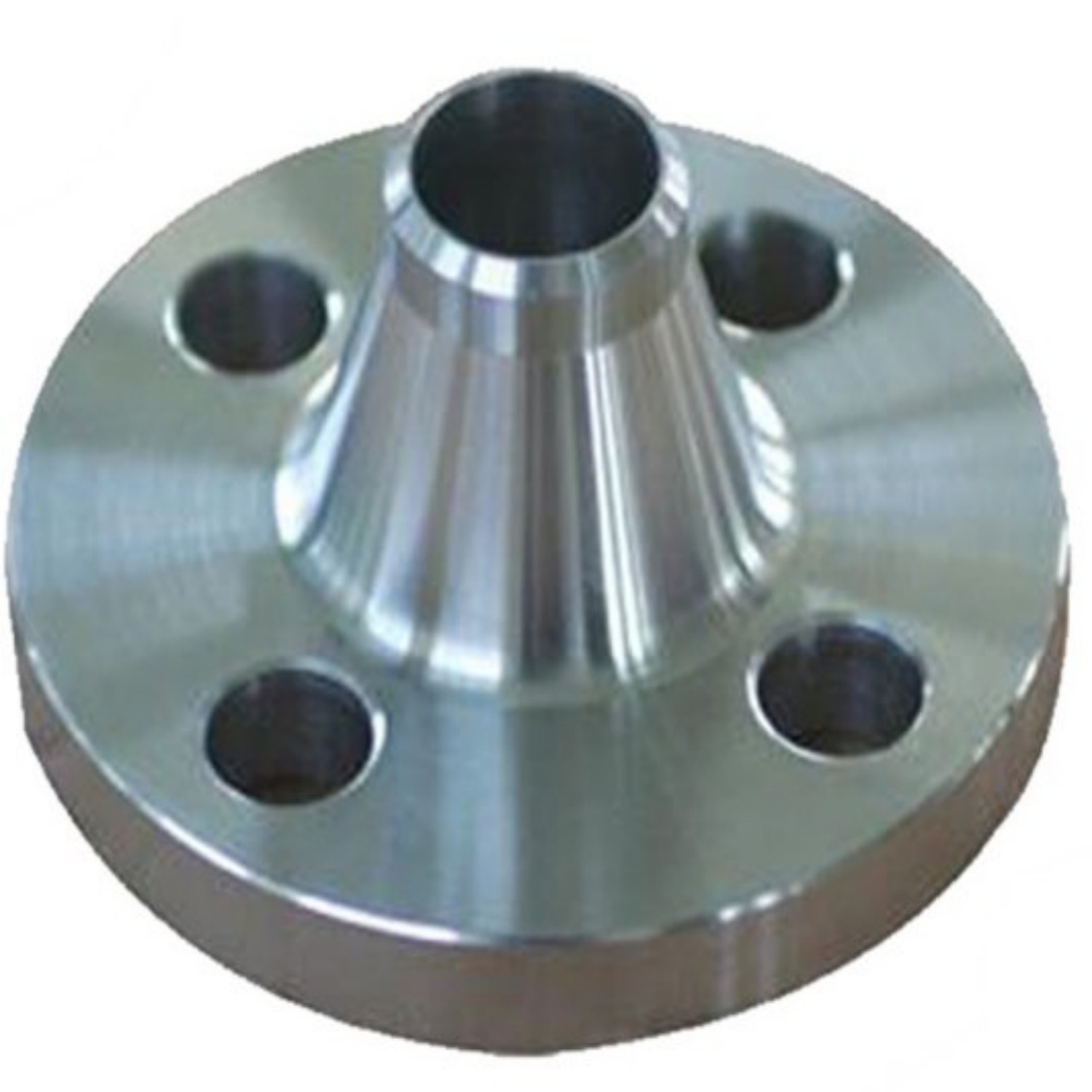

In the realm of industrial piping, the right choice of flange can significantly affect the performance and longevity of your systems. Among the most popular options today, Plate Flanges and Weld Neck Flanges are gaining attention for their unique advantages. While both serve the essential function of connecting pipes, they each have distinct characteristics that can make one more suitable than the other depending on the application. Plate Flanges are characterized by their simple design and ease of installation. They are lightweight and can be easily adapted to various pipe sizes. This versatility makes them a trending choice in industries seeking cost-effective solutions without compromising on quality. On the other hand, Weld Neck Flanges provide superior strength and are designed to withstand high pressure and temperature variations. The gradual transition from the flange to the pipe reduces stress concentrations, making them ideal for critical applications in oil and gas, chemical, and power generation sectors. As the global demand for efficient and reliable pipeline solutions continues to grow, understanding the differentiating factors between Plate Flanges and Weld Neck Flanges will be crucial for procurement decisions. Choosing the right flange type not only ensures optimal performance but also enhances the integrity of the entire piping system. With their unique features and applications, both options are outperforming competitors, making them essential components in today’s industrial landscape.

Plate Flange vs Weld Neck Flange Now Trending Outperforms the Competition

| Flange Type | Material | Applications | Pressure Rating | Weight (lbs) |

|---|---|---|---|---|

| Plate Flange | Carbon Steel | General piping applications | 150-300 psi | 5 |

| Weld Neck Flange | Stainless Steel | High-pressure pipelines | 300-1500 psi | 10 |

| Plate Flange | Aluminum | HVAC systems | 150 psi | 4 |

| Weld Neck Flange | Alloy Steel | Oil and gas industry | 600-3000 psi | 12 |

Related Products