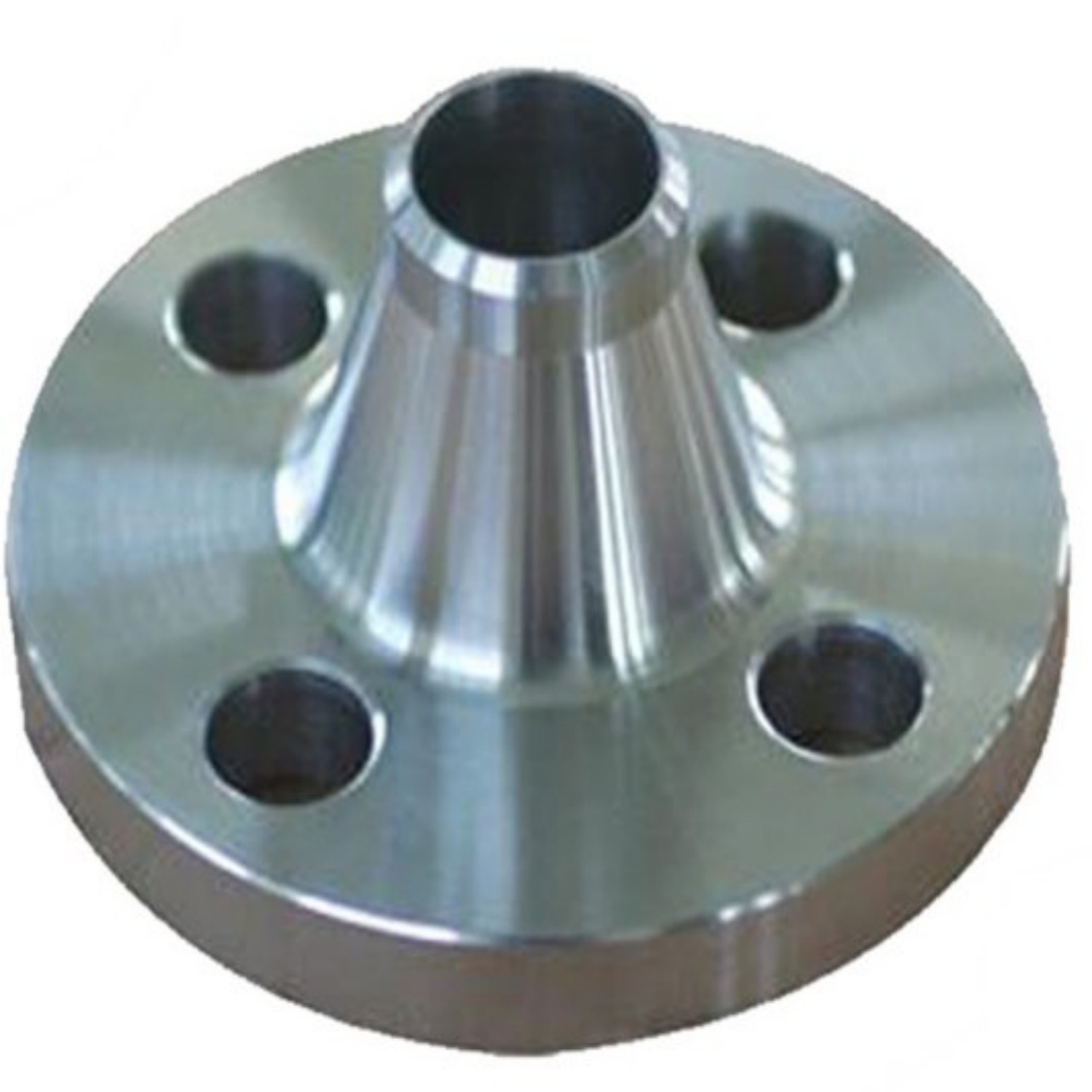

High-Quality Pl Flange Manufacturer: Trusted Supplier for Your Needs

As a dedicated supplier of PL flanges, I understand the importance of delivering high-quality products that meet the demands of various industries. Each flange is crafted using premium materials, ensuring durability and reliability in even the most challenging applications. I'm committed to providing solutions that support your projects, whether you're in construction, manufacturing, or another sector. We take pride in our attention to detail and rigorous quality control processes, which help ensure that every flange meets the highest standards. This means you can count on us not just for products but for a partnership that prioritizes your needs. By choosing us as your PL flange manufacturer, you're opting for excellence that can enhance your operations and overall success. Let me help you with your requirements, providing timely delivery and competitive pricing, contributing to the seamless flow of your business.

Pl Flange Manufacturer in 2025 Trusted by Pros

In 2025, the global landscape of pipeline equipment is evolving rapidly, and selecting a reliable PL flange manufacturer is paramount for industry professionals seeking quality and durability. Trust is built on experience and performance, and for those involved in procurement across various sectors, aligning with a manufacturer known for its commitment to excellence can significantly impact project success. Today’s buyers are looking for suppliers who not only deliver on time but also provide flanges that meet industry standards and regulations. The focus on quality control, innovative production techniques, and sustainable practices is reshaping the expectations of procurement managers worldwide. As the demand for durable and high-performance pipeline components increases, manufacturers that prioritize these aspects are poised to gain a competitive edge in the market. To navigate the complexities of the global supply chain, it is essential for buyers to partner with manufacturers that emphasize transparency and customer service. Comprehensive product offerings, certifications, and a strong track record in servicing diverse industries can instill confidence in procurement decisions. As 2025 approaches, those involved in the sourcing of pipeline equipment must stay informed about the trusted players in the market to ensure they are making the most informed choices for their operational needs.

Pl Flange Manufacturer in 2025 Trusted by Pros

| Material | Size (inches) | Pressure Rating (ANSI) | Standard | Finish |

|---|---|---|---|---|

| Carbon Steel | 3/4 | 150 | ASME B16.5 | Coated |

| Stainless Steel | 1 | 300 | ASME B16.5 | Polished |

| Ductile Iron | 2 | 150 | ASME B16.1 | Epoxy Coated |

| Alloy Steel | 3 | 600 | ASME B16.5 | Uncoated |

| PVC | 2.5 | Schedule 40 | ASTM D2467 | Smooth |

Related Products