Discount Custom Reducing Pipe Tee for Chemical Industry - Factory Direct

As a key player in the chemical industry, I understand that quality materials are essential for optimal performance. That’s why I’m excited to present our Custom Reducing Pipe Tee, designed specifically to meet the unique demands of this sector. Crafted with precision, our reducers seamlessly integrate into your piping system, ensuring reliability and efficiency. I know that finding the right balance between quality and cost is crucial. That's why we offer competitive pricing and attractive discounts for bulk orders, ensuring you stay within budget without sacrificing standards. Sourced directly from our factory, every piece goes through rigorous testing to meet industry specifications. By choosing our Custom Reducing Pipe Tee, you’re not just purchasing a product; you’re investing in enhanced durability and performance for your operations. Let's connect and discuss how we can support your business needs with the best solutions in the market!

Custom Reducing Pipe Tee for Chemical Industry Ahead of the Curve Global Reach

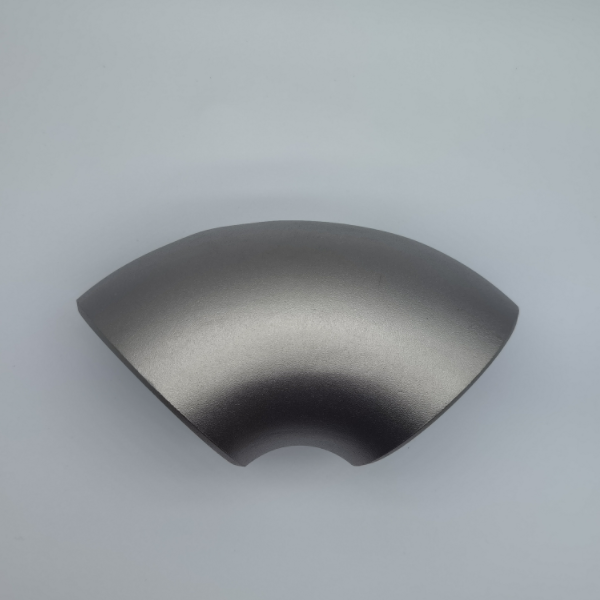

In the rapidly evolving chemical industry, ensuring seamless operations requires high-quality components that meet specific needs. Custom reducing pipe tees are vital in facilitating efficient fluid transfer while maintaining optimal pressure. These components not only enhance the workflow but also contribute to the safety and reliability of chemical processes. With advancements in technology and manufacturing techniques, purchasing custom reducing pipe tees has never been easier or more beneficial. One of the key advantages of sourcing custom reducing pipe tees from a reliable manufacturer is the flexibility in design and material selection. This means that buyers can tailor products to fit exact specifications, whether dealing with corrosive substances or high-pressure environments. Moreover, manufacturers are increasingly adopting global reach strategies, ensuring that businesses worldwide can access top-quality products without the usual logistical hurdles. This global availability not only streamlines procurement processes but also reduces lead times and costs, enabling companies to respond swiftly to market demands. As businesses continue to expand and innovate, the importance of partnering with suppliers who understand the unique challenges of the chemical industry cannot be overstated. By choosing custom reducing pipe tees tailored to specific applications, organizations can gain a competitive edge, enhancing efficiency and reducing downtime. As the global landscape continues to shift, now is the time for procurement professionals to invest in high-quality, customized solutions that will drive success in their operations.

Custom Reducing Pipe Tee for Chemical Industry Ahead of the Curve Global Reach

| Material | Diameter (inches) | Pressure Rating (psi) | Temperature Range (°F) | Application Area |

|---|---|---|---|---|

| Stainless Steel | 2 | 150 | -50 to 150 | Chemical Processing |

| Carbon Steel | 3 | 300 | -20 to 250 | Petrochemical |

| PVC | 4 | 100 | 32 to 140 | Water Treatment |

| HDPE | 6 | 80 | -40 to 140 | Agricultural |

| Alloy | 8 | 600 | -20 to 300 | Pharmaceuticals |

Related Products