Top China Manufacturer of High-Quality Ceramic Ball Valves

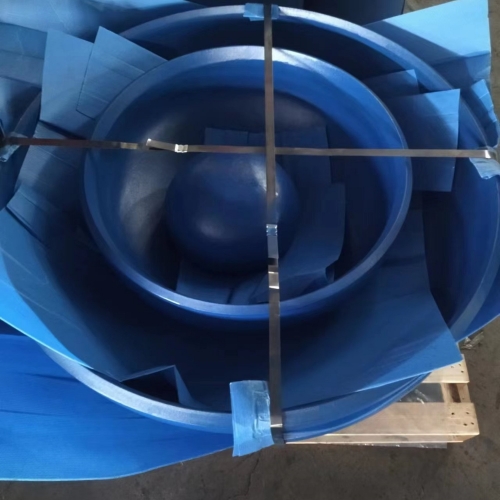

When I first encountered the Ceramic Ball Valve, I was impressed by its durability and efficiency. As a reliable choice for various industries, this valve ensures optimal performance in demanding environments. Manufactured in China, our Ceramic Ball Valves boast advanced technology and superior quality, making them an essential component for any production line. What I love most about these valves is their resistance to wear and extreme temperatures, which ultimately reduces the need for frequent replacements. Moreover, our manufacturing process prioritizes precision and reliability, so I can confidently say that these valves will meet your highest standards. Whether you’re looking for a solution for corrosive fluids or a product that requires minimal maintenance, the Ceramic Ball Valve could be the right fit for you. I encourage you to consider the benefits of partnering with a trusted manufacturer to enhance your operations. Let’s optimize performance together with our top-of-the-line Ceramic Ball Valves.

Ceramic Ball Valve Factory Dominates

In the ever-evolving world of industrial components, ceramic ball valves have emerged as a reliable solution for various applications due to their superior durability and resistance to corrosion and wear. As industries increasingly prioritize efficiency and sustainability, sourcing quality valves has become paramount for global buyers. A prominent player in the ceramic ball valve market is setting a benchmark with cutting-edge manufacturing processes that ensure each valve not only meets but exceeds international quality standards. This factory’s commitment to innovation and excellence means that it consistently invests in modern technology and skilled labor. This commitment results in products that offer exceptional performance and longevity, making them a cost-effective choice for industrial applications ranging from chemical processing to fluid transport systems. With a wide range of customizable options, clients can find tailor-made solutions that address their specific operational challenges, ensuring optimal functionality in diverse environments. Moreover, the emphasis on sustainable practices, such as minimizing waste during production and sourcing environmentally friendly materials, aligns with the growing global demand for sustainable manufacturing. For procurement managers and purchasing agents worldwide, partnering with a leader in the ceramic valve sector not only guarantees high-quality valves but also supports a vision of responsible and sustainable industrial advancement.

Ceramic Ball Valve Factory Dominates

| Dimension | Material | Pressure Rating (psi) | Temperature Range (°C) | Applications |

|---|---|---|---|---|

| 1 inch | Ceramic | 150 | -20 to 120 | Water, Gas |

| 2 inch | Ceramic | 200 | -20 to 150 | Oil, Chemicals |

| 3 inch | Ceramic | 250 | -20 to 180 | Wastewater |

| 4 inch | Ceramic | 300 | -20 to 200 | Pharmaceuticals |

Related Products