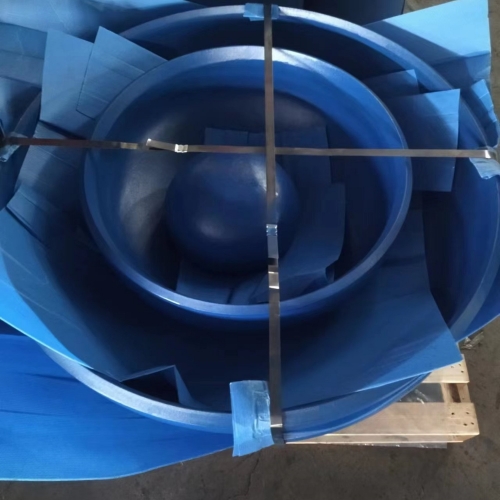

China Manufacturer of High-Quality Butterfly Isolation Valves

When it comes to sourcing reliable Butterfly Isolation Valves, I've found that quality and performance are key factors for B2B purchasers like us. These valves, designed for a variety of industrial applications, offer exceptional durability and efficiency. Being a manufacturer from China, I understand the importance of providing not just a product, but a solution that meets our customers’ unique needs. Our Butterfly Isolation Valves ensure smooth operation and easy maintenance, making them ideal for controlling flow in pipeline systems. The robust design and high-quality materials guarantee long-lasting service, which is essential for minimizing downtime and maximizing productivity. With a strong focus on innovation and customer satisfaction, we deliver valves that not only comply with international standards but also excel in functionality. If you’re in need of an efficient and cost-effective isolation solution, our valves represent the perfect blend of reliability and performance. Let’s connect to discuss how we can support your operational needs!

Butterfly Isolation Valve in 2025 Where Innovation Meets 2025

As we look towards 2025, the landscape of industrial components is evolving, with butterfly isolation valves at the forefront of innovation. These valves not only provide superior performance but also offer a range of features that align with the increasing demands for efficiency and sustainability in various sectors. The global marketplace is witnessing a shift towards automation and smart technologies, making the integration of advanced butterfly isolation valves a strategic choice for businesses aiming to enhance operational effectiveness. The butterfly isolation valve’s design allows for quick shut-off and minimal resistance to flow, which is particularly beneficial in applications ranging from water treatment to oil and gas industries. In 2025, we can expect further developments in materials and technology that enhance these valves' durability and performance. Features such as corrosion resistance and lightweight construction will be pivotal in meeting the stringent regulations and environmental standards set forth by industries worldwide. Moreover, the role of digitalization in valve systems cannot be overstated. As industries transform, the incorporation of IoT technologies into butterfly isolation valves will enable real-time monitoring and predictive maintenance, reducing downtime and optimizing operations. For global buyers, investing in innovative valve solutions will not only support immediate operational goals but also pave the way for a more sustainable future in industrial practices. The commitment to innovation in butterfly isolation valves in 2025 is not just about meeting today’s demands but also about anticipating the challenges of tomorrow.

Butterfly Isolation Valve in 2025 Where Innovation Meets 2025

| Parameter | Description | 2025 Expected Trends |

|---|---|---|

| Material | Commonly used materials include stainless steel, ductile iron, and PVC. | Increased use of corrosion-resistant materials. |

| Actuation Type | Manual, pneumatic, and electric actuators are available. | Shift towards electric actuators for precision control. |

| Applications | Used in water treatment, oil and gas, HVAC, and chemical processing. | Growing adoption in renewable energy systems. |

| Size Range | Available in sizes from 1 inch to 60 inches. | Trend towards larger sizes for industrial applications. |

| Standards Compliance | Compliant with ASME, API, and ANSI standards. | Increased focus on sustainability standards. |

Related Products