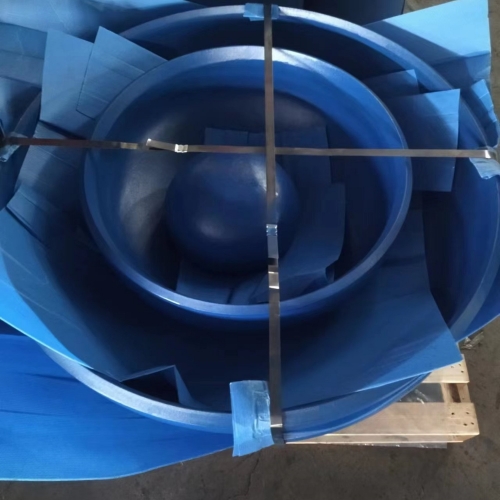

Factory Discount on Butt Weld Pipe Cap - Quality at Unbeatable Prices

When I think of top-quality solutions for piping needs, the Butt Weld Pipe Cap always comes to my mind. This essential fitting provides a reliable way to seal the ends of pipes, ensuring smooth operation and enhanced durability in various applications. I appreciate that they come at a discounted price direct from the factory, allowing me to maximize my budget without sacrificing quality. Whether you're in construction, manufacturing, or any industry that requires seamless connections, these caps are a no-brainer. They fit perfectly and are built to last, which means fewer headaches down the line. With my experience, I know that sourcing directly from a factory also means quicker turnaround times, getting my projects back on track. Trust me, when you need dependable piping solutions, investing in Butt Weld Pipe Caps is a decision you won’t regret. Let's make sure your projects flow smoothly!

Butt Weld Pipe Cap Factory From Concept to Delivery

In the realm of industrial manufacturing, the journey of a product from initial concept to final delivery is crucial for ensuring quality and reliability. For those seeking high-quality butt weld pipe caps, understanding this process is essential. The efficiency of manufacturing butt weld pipe caps begins with rigorous design and engineering, where state-of-the-art technology is utilized to create designs that meet the specific needs of diverse applications and industries. Once the design is finalized, the production phase employs advanced equipment and skilled labor to fabricate the caps from premium materials. This ensures that each piece meets strict international standards for durability and performance. Quality control checkpoints throughout the manufacturing process further guarantee that each cap not only aligns with the design specifications but is also capable of withstanding the demands of various environments. The final stage involves meticulous packaging and timely delivery logistics, ensuring that our customers receive their orders efficiently and in perfect condition. This comprehensive approach not only enhances customer satisfaction but also builds long-term relationships with global buyers looking for reliable solutions in pipeline equipment. Investing in this thorough approach from concept to delivery ensures that you receive the best butt weld pipe caps for your projects—combining quality, precision, and dependability.

Butt Weld Pipe Cap Factory From Concept to Delivery

| Process Stage | Description | Duration (Days) | Key Parameters |

|---|---|---|---|

| Design & Engineering | Initial design and engineering specifications for pipe caps. | 10 | Material selection, dimensions, pressure rating |

| Material Procurement | Sourcing of materials needed for production. | 15 | Steel grade, quantity, supplier certification |

| Manufacturing | Actual fabrication of pipe caps using various processes. | 30 | Welding technique, testing standards |

| Quality Assurance | Inspection and testing of finished products for defects. | 7 | Non-destructive testing, dimensional checks |

| Packaging & Delivery | Final packaging and shipping arrangements for delivery. | 5 | Packaging method, logistics |

Related Products