Top Factories for Quality Butt Weld Elbows – Expert Guide

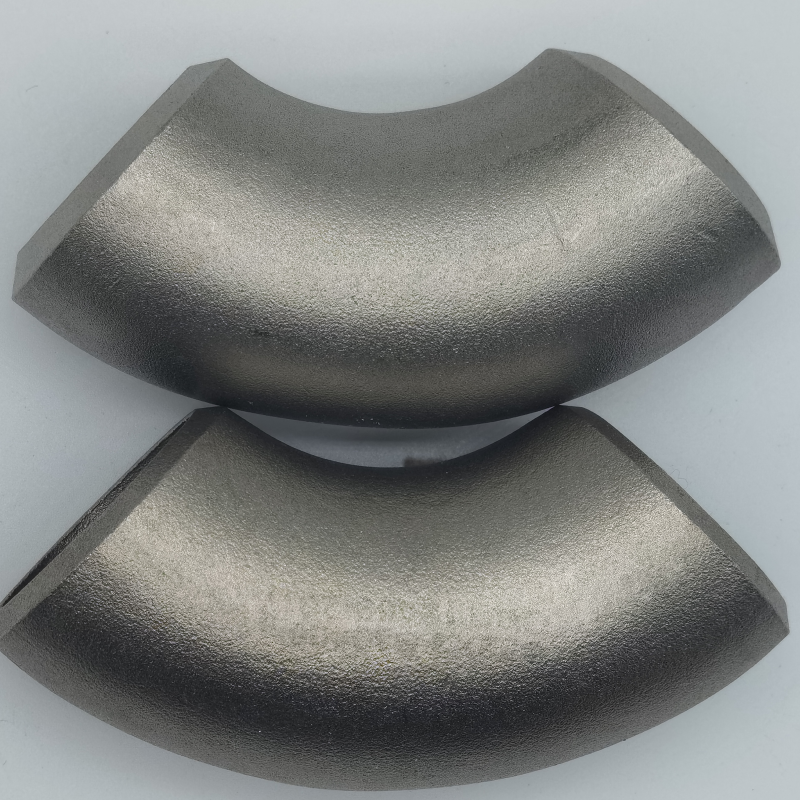

When I need reliable and durable piping solutions, I always turn to butt weld elbows. These connectors are essential for creating smooth transitions and turns in piping systems, ensuring optimal flow and minimal pressure loss. Whether I'm working with factories or complex industrial projects, the quality of the materials really matters. I can confidently say that butt weld elbows made from high-grade stainless steel stand the test of time, resisting corrosion and wear. If you’re considering a purchase, you’ll want to find a trusted supplier who understands the specific needs of your factory. I’ve always prioritized suppliers who offer excellent customer service and prompt delivery, making the buying process seamless. Choosing the right butt weld elbow is crucial for efficiency in operations, and I constantly recommend sourcing from experienced manufacturers. With the right elbow, I know my projects will lead to long-lasting and effective installations. Let's get your factory equipped today!

butt weld elbow For the Current Year Where Innovation Meets 2025

In the dynamic world of pipeline solutions, the butt weld elbow stands out as a crucial component for ensuring seamless connections in piping systems. As we approach 2025, innovation in manufacturing processes and material technology has redefined the standards of these essential fittings. Today's butt weld elbows not only meet stringent operational requirements but also enhance durability and performance, making them an ideal choice for diverse applications, from oil and gas to water distribution and beyond. The current advancements focus on producing butt weld elbows that are not only robust but also environmentally friendly. Manufacturers are increasingly utilizing advanced alloy materials that offer resistance to corrosion and wear, reducing the need for frequent replacements. Furthermore, the integration of smart manufacturing techniques allows for precise engineering and customization to meet specific project needs, enabling procurement professionals to source high-quality products tailored to their unique specifications. As global demand for reliable and efficient piping solutions continues to rise, now is the time for procurement professionals to explore innovative options in butt weld elbows. By considering factors such as material composition, sustainability, and manufacturing excellence, businesses can ensure they are investing in components that will stand the test of time while contributing to a more efficient and sustainable future in pipeline infrastructure. This is not just procurement; it's a strategic move towards a future of better engineering and sustainable resource management.

Butt Weld Elbow For the Current Year Where Innovation Meets 2025

| Material | Dimensions (inch) | Angle | Manufacturing Process | Applications |

|---|---|---|---|---|

| Carbon Steel | 1", 2", 3" | 90° | Welding | Oil & Gas |

| Stainless Steel | 1.5", 2.5" | 45° | Hot Forming | Chemical Processing |

| Alloy Steel | 2", 4" | 180° | Die Casting | Power Generation |

| PVC | 3", 6" | 30° | Injection Molding | Water Supply |

| Bronze | 1", 3" | 60° | Forging | Marine Applications |

Related Products