Top China Manufacturer of Alloy Steel Pipe Fittings for Your Needs

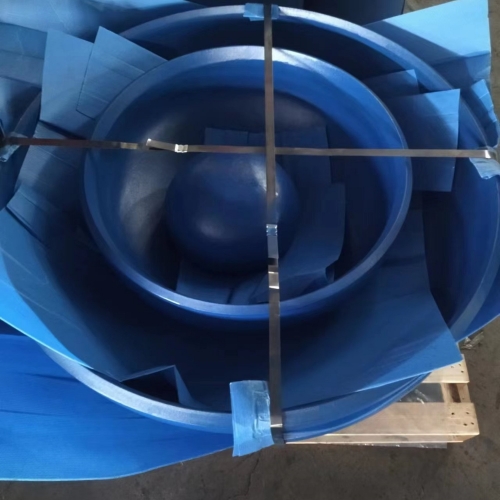

When it comes to alloy steel pipe fittings, I understand the importance of quality and reliability, especially for B2B buyers. Sourced directly from a leading manufacturer in China, our fittings are designed to meet the highest industry standards. I’ve seen firsthand how these fittings enhance the durability and performance of various applications, from construction to manufacturing. Each piece is crafted with precision, ensuring a perfect fit and exceptional strength, which can be crucial for your projects. Plus, with our competitive pricing and efficient delivery, I’m confident that we can support your needs effectively. Whether you’re working on a large-scale project or just need a small quantity, our alloy steel pipe fittings deliver the performance you expect. Partnering with us means you’re choosing a product backed by years of expertise and commitment to excellence. Let us help you elevate your operations with our top-notch fittings!

alloy steel pipe fittings Manufacturer Now Trending

In today's competitive market, the demand for high-quality alloy steel pipe fittings is on the rise, making it essential for procurement professionals to stay informed about leading manufacturers. Alloy steel pipe fittings offer superior strength and resistance to high temperatures and pressures, making them an ideal choice for various industries, including oil and gas, construction, and manufacturing. As a result, sourcing from reliable manufacturers ensures that businesses can maintain operational efficiency and safety standards. One of the key trends in this sector is the increased emphasis on sourcing from manufacturers that guarantee both quality and compliance with international standards. This trend is driven by the growing need for sustainable practices and durable materials. Manufacturers that invest in advanced technology and rigorous quality control measures are becoming more sought after, as they provide products that meet the stringent requirements of global projects. Buyers are encouraged to look for certifications and track records that reflect a commitment to excellence, ensuring that they partner with a manufacturer that can deliver on promises. Furthermore, as global supply chains evolve, it’s becoming critical for procurement teams to foster strong relationships with their suppliers. Engaging with manufacturers that offer customizable solutions can help businesses meet specific project needs while also benefiting from cost-effectiveness. The trend toward digital transformation in procurement processes, including the use of online platforms for sourcing and communication, is also reshaping how buyers interact with manufacturers. Staying ahead of these trends not only enhances procurement strategies but also leads to long-term partnerships that can drive innovation and success in a rapidly changing global market.

Alloy Steel Pipe Fittings Manufacturer Now Trending

| Product Type | Dimension | Material Grade | Application | Certification |

|---|---|---|---|---|

| Elbow | 1/2" to 24" | ASTM A234 WPB | Oil & Gas | ISO 9001 |

| Reducer | 1" x 3/4" to 10" x 8" | ASTM A403 WP316 | Chemical Processing | ASME B16.9 |

| Tee | 1" to 16" | ASTM A815 | Water Supply | API 5L |

| Flange | 1" to 48" | ASTM A182 | Construction | DIN |

| Caps | 1" to 18" | ASTM A234 | Pipelines | NACE MR0175 |

Related Products

Carbon Steel Elbow Black Mild Steel St20 Pipe Fittings Reducer Eccentric Concentric Reducer

Read More