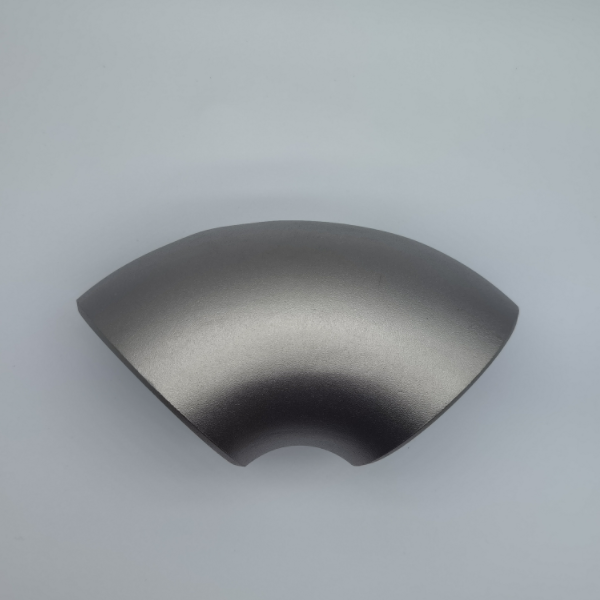

Wholesale Seamless Elbow Manufacturers: Quality Products at Competitive Prices

As a buyer searching for quality Wholesale Seamless Elbows, I understand the importance of having reliable connections for my projects. These elbows are designed to provide optimal flow and minimal pressure drop, making them essential for creating seamless transitions in piping systems. When I buy wholesale, I know I'm not just saving costs but also ensuring that I'm sourcing directly from reputable manufacturers who prioritize quality and durability. What really sets our seamless elbows apart is the precision in manufacturing, which guarantees a perfect fit every time. With various sizes available, I can easily find the right product for my specific needs. I appreciate the blend of functionality and affordability, as it allows me to complete my projects efficiently without compromising on quality. Partnering with trusted manufacturers means I can rely on prompt shipments and excellent customer support, making my purchasing experience smooth and hassle-free. Let’s make your operations more efficient with top-grade wholesale seamless elbows!

Wholesale Seamless Elbow Products Factory

When it comes to sourcing high-quality seamless elbow products, understanding the core attributes that make these components essential in pipeline systems is crucial for global buyers. Seamless elbows are manufactured to provide robust connections in various piping applications, ensuring minimal leakage and maximum durability. They are often made from superior materials, which can withstand high pressure and temperatures, making them ideal for industries such as oil and gas, water supply, and chemical processing. For global procurement teams, selecting a reliable supplier is key. Factors such as production capabilities, quality assurance measures, and industry certifications should be prioritized. Partnering with a manufacturer that leverages advanced technology and stringent quality control processes can significantly reduce the risks associated with sourcing these critical components. Additionally, having a flexible supply chain to accommodate varying order volumes and delivery schedules is essential for maintaining operational efficiency. Moreover, understanding the customization options available can enhance procurement strategies. Whether it’s specific sizes, angles, or material grades, a reputable supplier can provide tailored solutions that meet unique project requirements. As businesses strive to optimize their supply chains and ensure the integrity of their systems, seamless elbow products stand out as a vital investment, catering to both performance and reliability in demanding environments.

Wholesale Seamless Elbow Products Factory

| Product ID | Material | Size (mm) | Weight (kg) | Applications | Certification |

|---|---|---|---|---|---|

| ELB001 | Stainless Steel | 25 | 0.5 | Plumbing, HVAC | ISO 9001 |

| ELB002 | Carbon Steel | 32 | 0.7 | Oil and Gas | ASTM A234 |

| ELB003 | Alloy Steel | 50 | 1.5 | Chemical Processing | ASME B16.9 |

| ELB004 | PVC | 40 | 0.3 | Irrigation | CE Certified |

| ELB005 | Bronze | 20 | 0.4 | Marine Applications | DNV GL |

Related Products