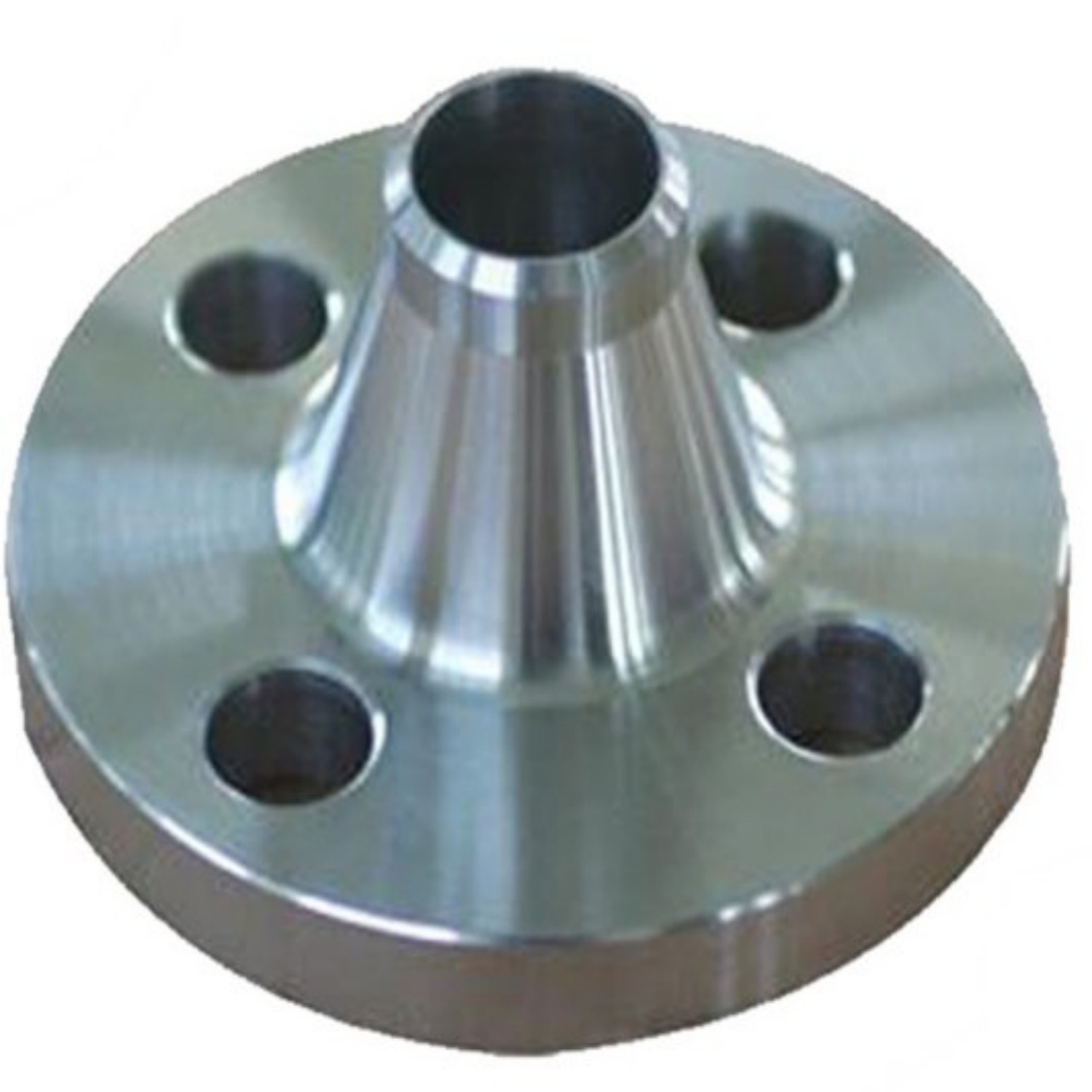

Welding Neck Flange from Trusted Factories for Quality Assurance

When I think about reliability in piping systems, Welding Neck Flanges come to my mind instantly. These flanges are designed to provide exceptional strength and integrity, making them perfect for high-pressure applications. If you are considering buying flanges, it’s important to choose the right type for your factory’s needs. Welding Neck Flanges connect seamlessly with pipes, allowing for easy alignment and stability. By investing in these flanges, you’ll be ensuring a secure and leak-proof connection that stands the test of time. I’ve noticed that many factories appreciate the versatility of these components, especially in challenging environments. When sourcing Welding Neck Flanges, I recommend checking out trusted suppliers who understand the nuances of industrial needs. This way, you can be confident in the quality and performance of the flanges you purchase for your operations. Your setup deserves nothing less than the best!

Welding Neck Flange Your Trusted OEM Partner Your End-to-End Solution

When it comes to sourcing high-quality welding neck flanges, establishing a reliable partnership with an Original Equipment Manufacturer (OEM) is essential. As the global market continues to expand, companies looking for robust and durable pipeline solutions need a partner that can deliver comprehensive support. From the initial design phase to the final product delivery, a trusted OEM can provide end-to-end solutions tailored to meet the specific needs of your projects. Welding neck flanges are critical components in various industries, ensuring safe and efficient connections in pipeline systems. Their unique design not only enhances strength but also allows for easy alignment and reduces stress on piping systems. By partnering with a knowledgeable OEM, global purchasers can benefit from customized manufacturing options, ensuring that every flange meets the exact specifications required for each application. This collaboration can significantly improve project timelines and outcomes. Moreover, a reputable OEM partner offers more than just manufacturing capabilities; they provide engineering expertise, testing services, and quality assurance throughout the entire production process. When selecting a partner, it is essential to look for one that has a proven track record in compliance with international standards, reinforcing confidence in the reliability and performance of their products. This partnership can help streamline procurement processes, reduce costs, and ultimately contribute to the long-term success of your business.

Welding Neck Flange: Your Trusted OEM Partner, Your End-to-End Solution

| Dimension | Material | Standard | Pressure Rating | Finish |

|---|---|---|---|---|

| DN50 | Carbon Steel | ASME B16.5 | 150 psi | Smooth |

| DN100 | Stainless Steel | ANSI B16.5 | 300 psi | Polished |

| DN150 | Alloy Steel | API 605 | 600 psi | Coated |

| DN200 | Duplex Steel | EN 1092-1 | 900 psi | Smooth |

Related Products