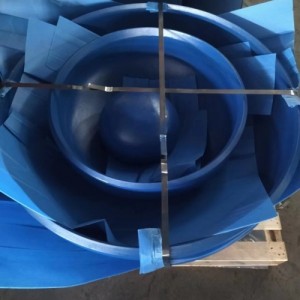

High Pressure Pipe End Cap

Product Overview

Pipe caps are fittings used to seal the ends of pipes, ensuring a tight seal and preventing the ingress of impurities or leakage. They are widely used in industries such as petroleum, chemical, natural gas, shipbuilding, power generation, and construction.

Product Features

- A variety of materials: carbon steel (ASTM A234 WPB), stainless steel (304/316), alloy steel (A860 WPHY 52/60/70), etc., to meet the needs of different media.

- Pressure Rating: Complies with ANSI/ASME B16.9 standards, supporting Class 150 to Class 2500.

- Strong Sealing: Precision machining ensures a tight fit with pipe ends, eliminating the risk of leaks.

- Corrosion Resistance: Available with galvanizing, epoxy coating, or anti-corrosion treatment for harsh environments.

- Connection Methods: Butt Weld, Threaded, and Socket Weld.

Specifications

- Size range: 1/2″ to 48″ (DN15-DN1200), custom sizes available.

- Wall thickness: Sch 10/40/80/160, or custom sizes available.

- Compliant standards: ASME B16.9, ASTM A234, MSS SP-75, EN 10253, etc.

Applications

- Pipeline end sealing

- Equipment interface protection

- Temporary plugging (maintenance or testing)

- High-pressure/high-temperature fluid pipelines

Why choose our Pipe Caps?

- Strict quality inspection: 100% hydrostatic testing, dimensional inspection, and material quality control (MTC) certification.

- Fast delivery: Standard models are in stock and urgent orders can be accommodated.

- Customization: Special materials, sizes, and surface treatments are available.

Customized Services

We understand that different customers may have unique requirements for pipe caps in their piping system projects, so we offer professional customization services. Whether you require pipe caps with special materials, sizes, or shapes, or require corrosion protection, thermal insulation, or special coatings to withstand extreme environments or special media, our dedicated team can customize the design and production based on your specific requirements, ensuring you receive the caps that best meet your project needs. We will collaborate with you throughout the entire process, from design development to product delivery, ensuring every step is carefully controlled to ensure the quality and performance of your customized products meet your expectations.

Mila