High-Quality Butt Welded Elbow Supplier for Your Plumbing Needs

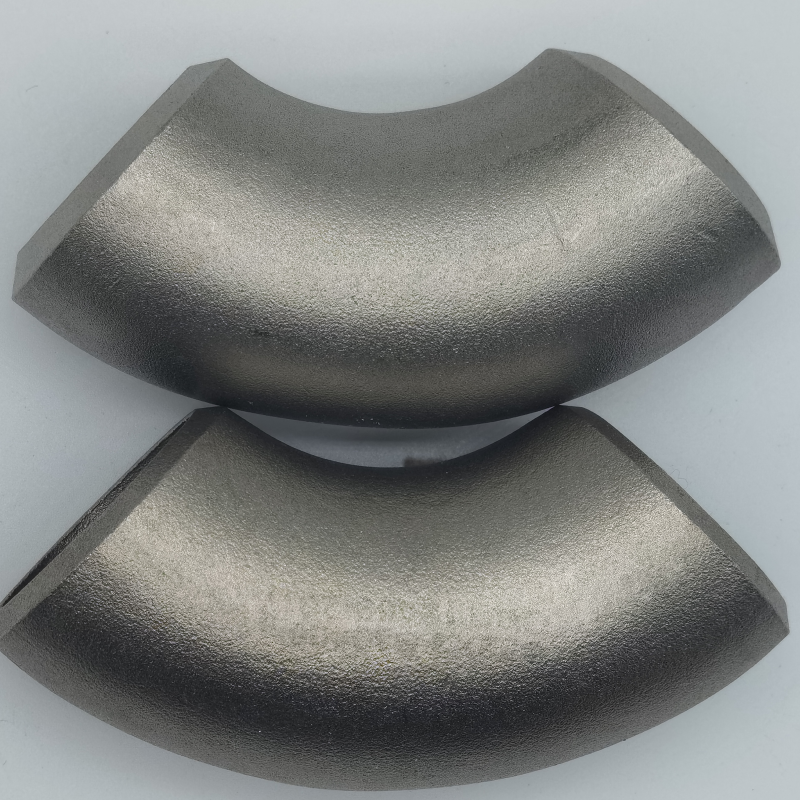

When it comes to reliable piping solutions, I always recommend high-quality butt welded elbows. These fittings are crucial for achieving smooth and efficient fluid flow in various applications. With a robust design that ensures strength and durability, they are perfect for everything from industrial to commercial use. I understand that finding a trustworthy supplier is essential; you need someone who offers products that meet industry standards. These butt welded elbows come in a variety of sizes and materials to fit your specific requirements, ensuring quality that you can depend on. Working with a top-notch supplier can make a world of difference; I strive to provide you with unparalleled service and expertise in sourcing the best products for your needs. Don't settle for less when it comes to your piping systems—choose high-quality butt welded elbows that achieve optimal performance. Trust me; your projects deserve the best.

Butt Welded elbow Products Sets the Industry Standard

Butt welded elbows are crucial components in pipeline systems, playing an essential role in directing flow and reducing turbulence. By setting the industry standard, these products ensure maximum efficiency and reliability in various applications, from industrial manufacturing to infrastructure development. The precision in design and manufacturing processes contributes to their superior performance, making them a preferred choice for global buyers looking for durability and quality. In today's competitive market, sourcing high-quality butt welded elbows can be a daunting task. However, understanding the technological advancements and manufacturing practices can help global purchasers make informed decisions. The ability to adapt to varying standards and specifications is vital, as different regions may have unique requirements. Top manufacturers utilize advanced welding techniques and rigorous quality control measures to produce elbows that not only meet but exceed industry benchmarks. Investing in premium butt welded elbows means investing in long-term success for any project. With enhanced resistance to pressure, temperature fluctuations, and corrosion, these products promise reliability and cost-effectiveness in the long haul. As the industry continues to evolve, staying ahead with high-quality pipeline equipment is not just an option; it's a necessity.

Butt Welded Elbow Products Sets the Industry Standard

| Product Type | Material | Size (inches) | Application | Certifications |

|---|---|---|---|---|

| 45° Elbow | Stainless Steel | 1 | Plumbing | ISO 9001 |

| 90° Elbow | Carbon Steel | 2 | Chemical Processing | ASME |

| Reducing Elbow | Alloy Steel | 1.5 | Oil & Gas | API |

Related Products